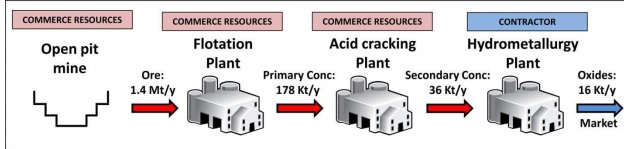

Commerce Resources (CCE.V) has now confirmed the preliminary bench scale results of the metallurgical leach test work during pilot plant operations, where the ore from the Ashram Project is being tested. This pilot plant was based on a single-leach process, as prior bench scale work strongly indicated steps could be reduced with efficiency maintained, or potentially improved, compared to the double-leach process that was previously piloted.

With the success of the single-leach pilot, the double-leach process has now been replaced and the overall process made more cost efficient. Although not achieved from this pilot, Commerce also indicated that the single-leach process may allow for an increase in overall recovery, which would further bolster the process.

For now, we’re glad the single leach process is working on the pilot plant level, and we’re looking forward to see Commerce trying to improve the current results. Keep in mind the bench scale test work has indicated the recovery rate could be increased to 76% (up from the current recovery rate of 71%) and this would be another important step to boost the economics of the Ashram Project.

We also briefly discussed these results with Darren L. Smith, Ashram’s Project Manager

Darren, a recovery rate of 71% is obviously pretty good, but in October, Commerce released a statement saying it has been able to reach a recovery rate of 76. What caused the difference between the 76% result of the bench scale tests and the pilot plant test?

Well, there were several reasons. One was a slight overdose of a reagent during a precipitation step that led to the loss of some REEs in the leach process (this is why we said we had to implement a minor operational adjustment). So basically, we will need an even lower amount of reagents, and that actually is a positive thing.

Secondly, the incomplete washing of the residue prior to the magnetic separation phase could also have been a contributing factor. Both of these issues are very minor and easy to correct. The main reason is that these were just the initial scale up pilots and only a couple residues were tested through the magnetic separation stage to confirm residue quality. The primary goal was demonstrating we could produce residues using a simpler, more easily controlled process that can be upgraded to those comparable that were produced on the bench scale.

So our goal was to achieve a concentrate containing >40% TREO @ >70% overall recovery. Based on these first two mini-pilots, we are very confident that overall recoveries may improve to a minimum 76% (as proven during the bench scale tests) and further from there.

Go to Commerce’s website

The author holds a long position in Commerce Resources. Commerce is not a sponsor of this website, but Zimtu Capital is. Please read the disclaimer