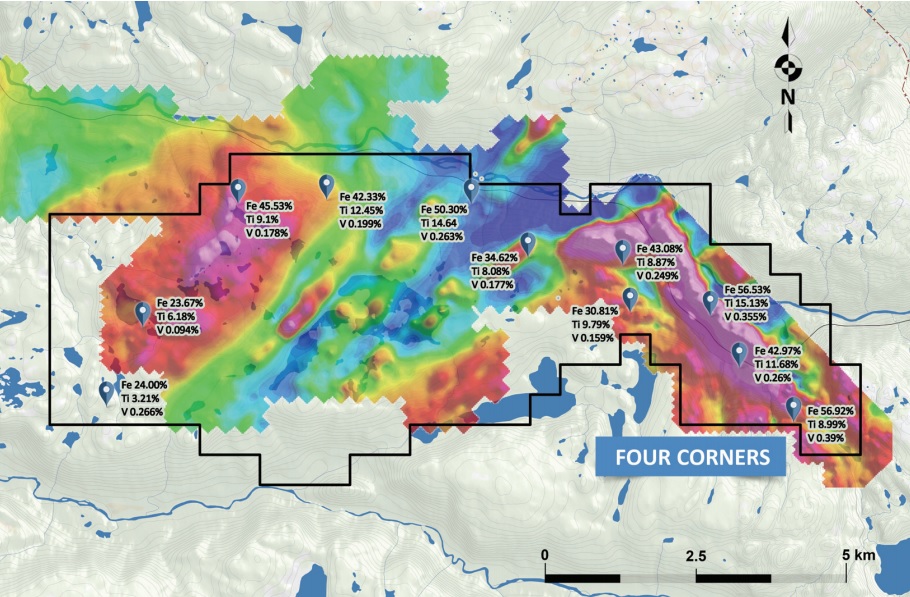

Delrey Metals (DLRY.C) has reported the updated assay results from its Four Corners project in Newfoundland in Labrador as the company’s consultants have now used a metaborate fusion assay method to re-sample some of the historic drill core. Applying the metaborate fusion method should result in a more complete digestion of some mineral species showing higher recovery rates over the standard four acid digestion method that has been used in the past.

Applying the new method has indeed increased the vanadium pentoxide recovery by 14-28%, and the average assay results of the three main metals (iron, titanium and vanadium) were respectively 35.07% Fe, 10.28% TiO2 and 0.22% V2O5. After applying a normal Davis Tube recovery, the Delrey team was able to increase the average grade of the concentrate to 63.1% Fe and 0.64% V2O5 which means the iron ore product meets the Fe-grade requirements to be shipped overseas to end users. It will be interesting to see if Delrey will be able to market the high-vanadium iron ore concentrate, and what the pricing of such a concentrate will be.

We feel the titanium component may prove to be at least as valuable as the iron and vanadium content. A head grade of in excess of 10% TiO2 is excellent, and the quoted recovery rates north of 80% indicate Delrey has a good shot at separating the titanium metal from the iron ore concentrate and sell it as a different product.

More testing will obviously be needed, but it does look like Delrey Metals could be producing three sought-after metals from its Four Corners project, and we will keep an eye on the developments this year.

Go to Delrey’s website

The author has no position in Delrey Metals. Please read the disclaimer