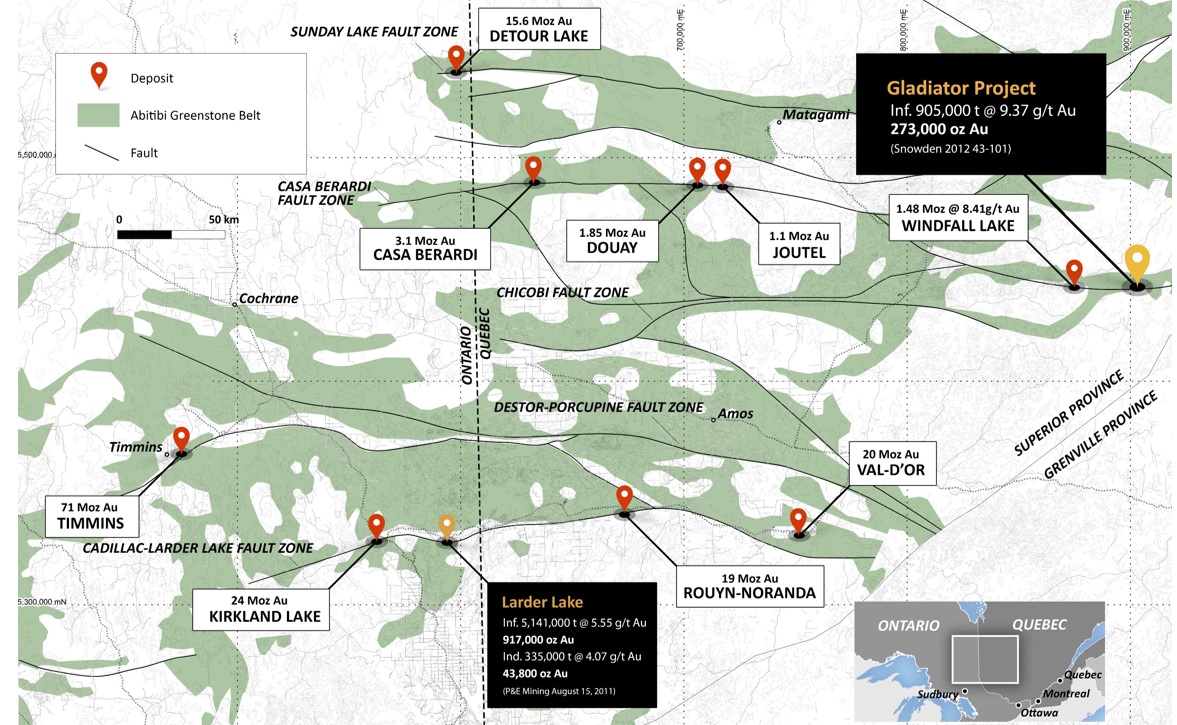

Earlier today, Bonterra Resources (BTR.V) released the long-awaited results from its preliminary metallurgical test work on samples from its high grade Gladiator Gold Deposit in Québec.

Completing metallurgical studies are a very important milestone in the development process of a gold project. You can have as much gold as you want in a resource in the ground, but if you can’t get it out of the rock easily, it really is just a bunch of worthless rock. So….. one of the biggest de-risking mechanisms for any gold mining project, is being able to extract the gold easily from the rock through good metallurgical processing parameters, and to recover as much gold with as little effort, capital and ongoing operating costs as possible. This sometimes can the key component in order to justify the economics of pushing a project towards a construction or production decision, to generate a profit.

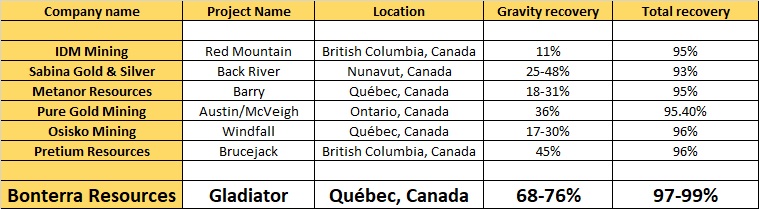

To start off, the Gladiator deposit yielded up to 76.1% recovery in the gravity circuit, and on average for all grinding sizes (coarser to fine) yielded greater than 70% gravity recovery. This confirmed the presence of a significant amount of free gold in the mineralized system. And that’s exceptional when compared to its peers across Canada / USA, as most ‘competitors’ reported average gravity recovery rates of 15% to 40%. Noting that all tested grinding sizes yield excellent gravity recoveries, it will allow for some flexibility when designing the crushing and grinding circuits. This could potentially save Bonterra an important part of its initial capex, but it coult also allow the company to reduce its operating expenses.

On average, greater than 70% of the gold reports to the gravity circuit at all grinding sizes, which potentially contributes to substantial capital reductions in the grinding circuits, potential lower reagent consumption, and highlights an opportunity for significant savings in the future processing parameters at Gladiator,”

Peter A. Ball, VP Operations.

To add to the excellent gravity recoveries, total recovery results were also well worth the wait as the combination of gravity and gravity-tail flotation tests resulted in a recovery rate of around 97%. The final icing on the cake, if even needed, the tests using gravity and gravity-cyanidation indicated the recovery rate could exceed 99%.

Not only are these amazing results (for both processing scenarios), there also is one important piece of information to harvest from these results. The difference between the recovery rates of the flotation circuit and the cyanide circuit is just 2%, which means Bonterra will have to do some trade-off studies to figure out if a cyanide leaching circuit would even make sense.

“Potentially not requiring a cyanide leaching circuit minimizes the environmental footprint of any future mining operation and could also improve potential future process economics of the project.”

Nav Dhaliwal, CEO

We don’t think Bonterra will put in the cyanide circuit as the NPV8% of a 150,000 oz/year production scenario wherein 2% more gold (3,000 oz/year) would be recovered would be just C$22M, based on a gold price of C$1700/oz. This means that if a cyanidation circuit would cost more than C$22M, Bonterra might be better off by just going for a flotation circuit as recovering less gold might actually result in a higher net present value. Of course, a final decision will only be made once Bonterra has all parameters as everything will depend on the total size of the resource and the expected average production rate (as well as the access to capital).

Another interesting fact is that the “Feed Grade” head assay results from the metallurgical testing ranged from 8.0 g/t Au to 10.0 g/t Au and showed excellent grade reconciliation with initial drill hole assays.

Considering Bonterra’s gravity and total recovery rates are easily beating the results from some peers in Canada and USA (see the table below, note, these results are rounded and not necessarily definitive), we dare to say these preliminary metallurgical results are absolutely excellent.

These results are extremely important as they confirm the excellent “clean rock” characteristics of the deposit, and the very low sulphide content such as arsenopyrite, which some of their neighbours have in their gold systems. Considering this is the very first time Bonterra has released any recovery rates of the Gladiator gold ever, this update should ease the concerns some investors might have. Not only is the gold recoverable, the actual recovery rates are exceptionally high, whilst the high gravity concentrate recovery rate indicates the ultimate processing cost (in dollars per tonne) will reside in the lower quartile compared to its peers.

The company is currently aggressively drilling the property as part of an ongoing 70,000 meter exploration program to increase the total gold resource at Gladiator. A resource update is expected for the second half of this year and that will be the second major component of a PEA which could be expected shortly thereafter. Bonterra Resources is slowly ticking all the boxes in its quest to build Québec’s next gold mine.

Go to Bonterra’s website

The author has a long position in Bonterra Resources. Bonterra isn’t a sponsor of the website, but we were compensated by a third party. Please read the disclaimer