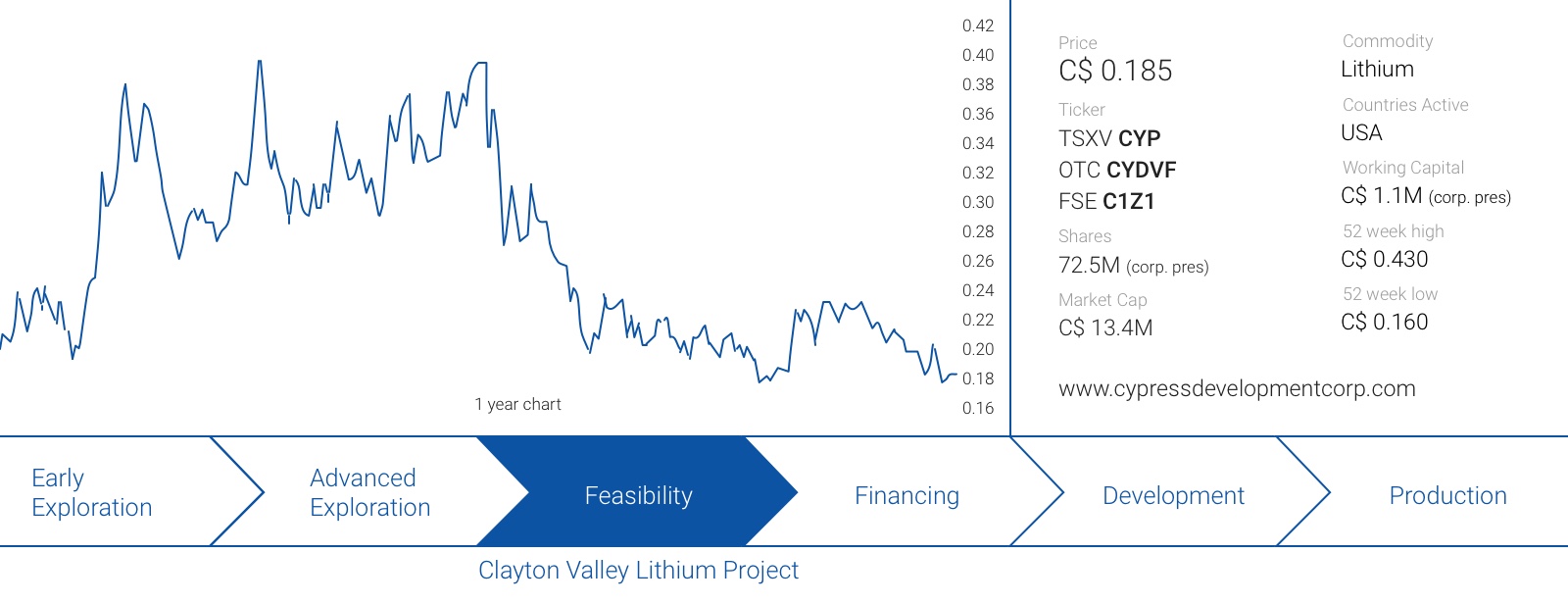

Cypress Development Corp. (CYP.V) ticked an important box last week as the company released the results of its metallurgical test work conducted on the Clayton Valley lithium project in Nevada. Ever since we have been keeping an eye on Cypress, this was an important part of the puzzle as the additional met work was supposed to increase the confidence in the metallurgical assumptions used in the PEA, and to increase the credibility of the PEA in general.

About the recently completed test program

Cypress has been working with Continental Metallurgical Services in Montana for several months now in an attempt to further define and fine-tune the metallurgical component of its economic studies at the Clayton Valley Lithium project. In particular, Cypress wanted to make sure the flow sheet it defined for Clayton Valley would actually work in the real world as well.

The lab simulated the operating circumstances based on the assumptions in the PEA (the agitated tank leaching stage at the specific temperatures used in the Economic Study, the leaching time, etc.).

The Montana-based lab ran a number of scenarios using a temperature range lower than the 70-90 degrees used in the PEA as well as a range of leaching times (between 1 and 4 hours, versus the 2-hour leaching time used in the PEA). As the metallurgical test work was also conducted on bulk composites from property-wide drill cores, it’s fair to assume the recovery results and acid consumption levels should be pretty consistent throughout the Clayton Valley property.

What we were looking for: recovery rates and acid consumption levels

In its Preliminary Economic Assessment, that was released in September and filed in October, Cypress Development had to use some assumptions for its economics, and the market – understandably – wanted to make sure Cypress was effectively able to realize these numbers. The main focus of the metallurgical program was to figure out the total recovery rate of the lithium as well as the acid consumption levels.

A. The recovery rates

In the PEA, Cypress used a recovery rate of 81.5% for the lithium in its claystone, and now the updated metallurgical test results have indicated an average lithium extraction rate of 75-83%. It’s fair to say the PEA assumptions have now proven to be realistic. Granted, the midpoint of the 75-83% recovery rate (79%) is lower than the 81.5% used, but keep in mind Cypress’ Clayton Valley project has just completed a PEA, and more test work will obviously be needed to further optimize the flow sheet to increase the recovery rate even further.

Considering Cypress’ test work has now confirmed the assumptions used in the PEA are credible, the main focus will now be on the next phase of the commercialization of the lithium product. It’s more important to gain knowledge to be able to convert the Pregnant Leach Solution into a saleable product rather than boosting the recovery rate by an additional percent or two, as that could easily be revisited as part of the feasibility study met work.

B. The acid consumption levels

A second important box that had to be ticked was the acid consumption level. A company can always boost the recovery rates even more, but then it’s always a question about diminishing marginal returns; it doesn’t make much sense to double the acid consumption for a 2% increase of the recovery rate as the higher acid consumption levels would cost you more than the additional revenue you’d generate.

In the PEA, Cypress used a sulfuric acid consumption level of 100 kg/t, and based its cutoff grade for the open pit resource on a consumption level of 125 kg/t.

The recent test work has indicated an average acid consumption level of 85-132 kg/t, and the midpoint of that range is approximately 109 kg/t. Slightly higher than the number used in the PEA, but lower than the 125 kg/t used to determine the cutoff grade of the lithium resources, so it’s once again reasonable to call these results ‘in line with the PEA assumptions’, and definitely very reasonable.

What’s next for Cypress Development?

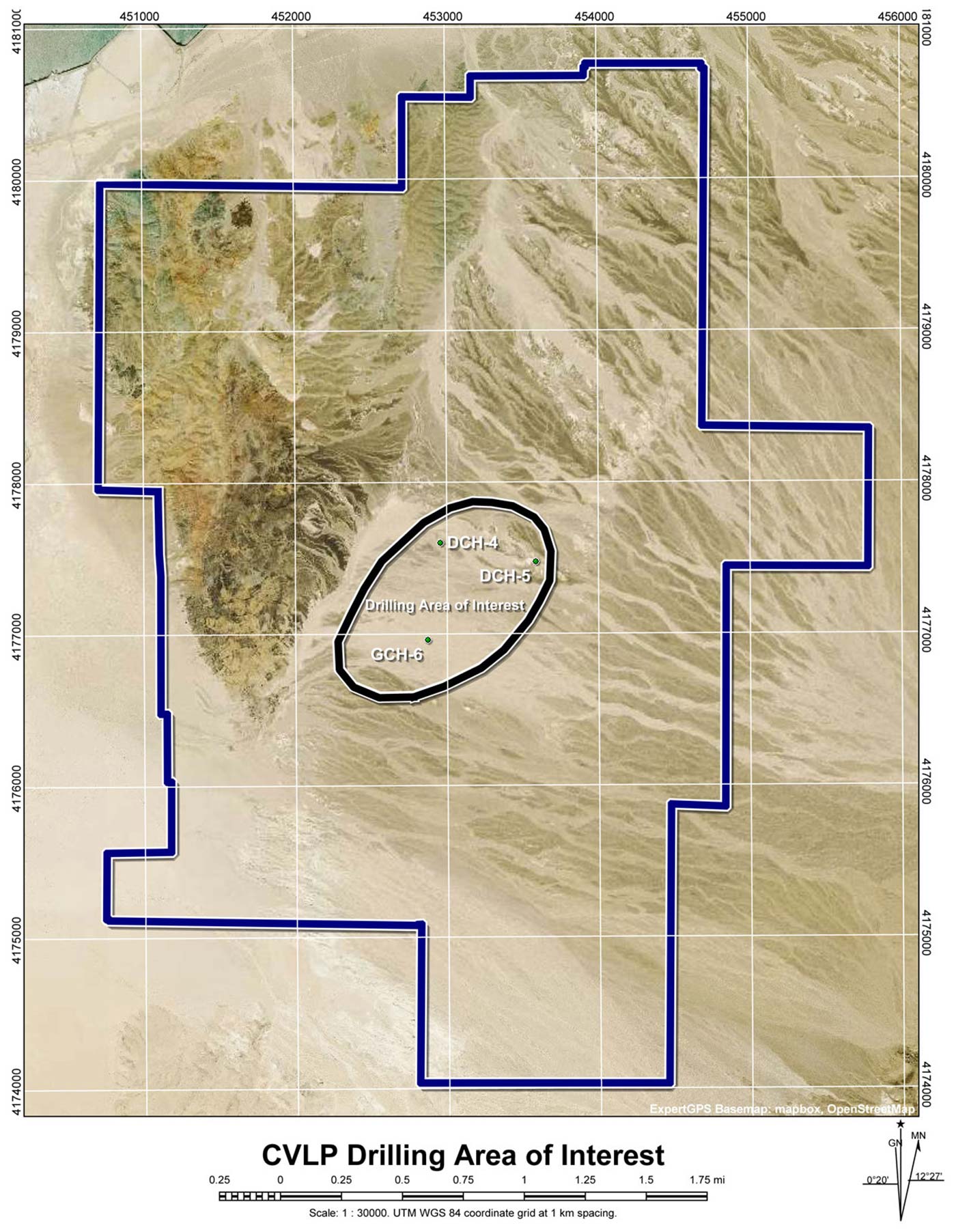

Cypress’ current infill drill program should be completed within the next few weeks (it’s a small drill program of just 500-800 meters of core drilling), and we would expect the drill program to confirm the grades and thickness of the claystone layer on the property. The drill program is aiming to upgrade some of the current resources into a higher category and there’s one specific area of interest Cypress will be focusing on almost right in the middle of the land package in between holes DCH 4&5 and GCH 6. As it’s a core drill program, Cypress will also be able to use the samples for further metallurgical testing activities, later this year.

We aren’t expecting any surprises here, and the data will be used for the upcoming pre-feasibility study, which should be completed next quarter. Cypress has engaged Ausenco Engineering as lead consultant for the pre-feasibility study as Ausenco has plenty of experience with lithium projects all over the world.

The lithium (carbonate) price is still trading at around $9,000 per tonne

Although the share prices of most lithium companies have been very weak lately, there doesn’t seem to be a fundamental reason that justifies this weakness. Sure, the big ‘hype moment’ in the lithium sector is over, but as the price for a tonne of lithium carbonate remains trading around $12,000/t according to Platts there’s absolutely no reason to be unhappy as this would be an excellent long-term price level. Orocobre has been guiding for an average price level of $9,000/t this quarter due to short-term price fluctuations, and we are unsure why their price guidance is approximately 25% lower than the Platts price.

In fact, in a report we published in November last year, we specifically referred to a lithium carbonate price of $9,100 per tonne, and according to our calculations, this would still result in an after-tax Net Present Value (using an 8% discount rate) of approximately US$600M or C$800M and an after-tax IRR of around 20%. Should we indeed use Platt’s price of $12,000/t, the aftet-tax NPV8% would very likely be around US$1.2B (C$1.6B) with an IRR of around 30%.

And that’s good enough for an asset in a safe jurisdiction with a mine life of several decades to be built and we remain convinced this Nevada-based asset will still attract a lot of attention upon the completion of the pre-feasibility study.

Conclusion

We were a bit surprised to see the subdued reaction of the market on the updated metallurgical test results as for us, the positive outcome is an important piece of the puzzle to prove up the value of the Clayton Valley lithium project.

Further optimization will be necessary to advance the project to the feasibility stage, but we don’t expect any negative surprises in the upcoming pre-feasibility study. We would expect the current round of infill drilling to confirm the robust resource used for the Preliminary Economic Assessment, and would expect the NPV and IRR to be in line with the PEA results.

Cypress Development will perhaps use a more conservative lithium price for its base case scenario, but we don’t care too much about that, as we already used a lower lithium price in our previous report to figure out a conservative base case based on a lithium carbonate price of $9,100/t. With lithium carbonate trading at around $12,000/t according to Platts, we are very confident the upcoming pre-feasibility study will show very robust economics.

Disclosure: Cypress Development is a sponsor of this website. The author has a long position in Cypress Development.