After several years of radio silence, the Rare Earth Element sector finally got some well-deserved attention as the mainstream media and US political world suddenly seems to realize the trade war with China might lead to unwanted and unforeseen circumstances. After all, pretty much every country in the world, including the USA, is still depending on China for its REE needs and new independent supply sources would be very welcome.

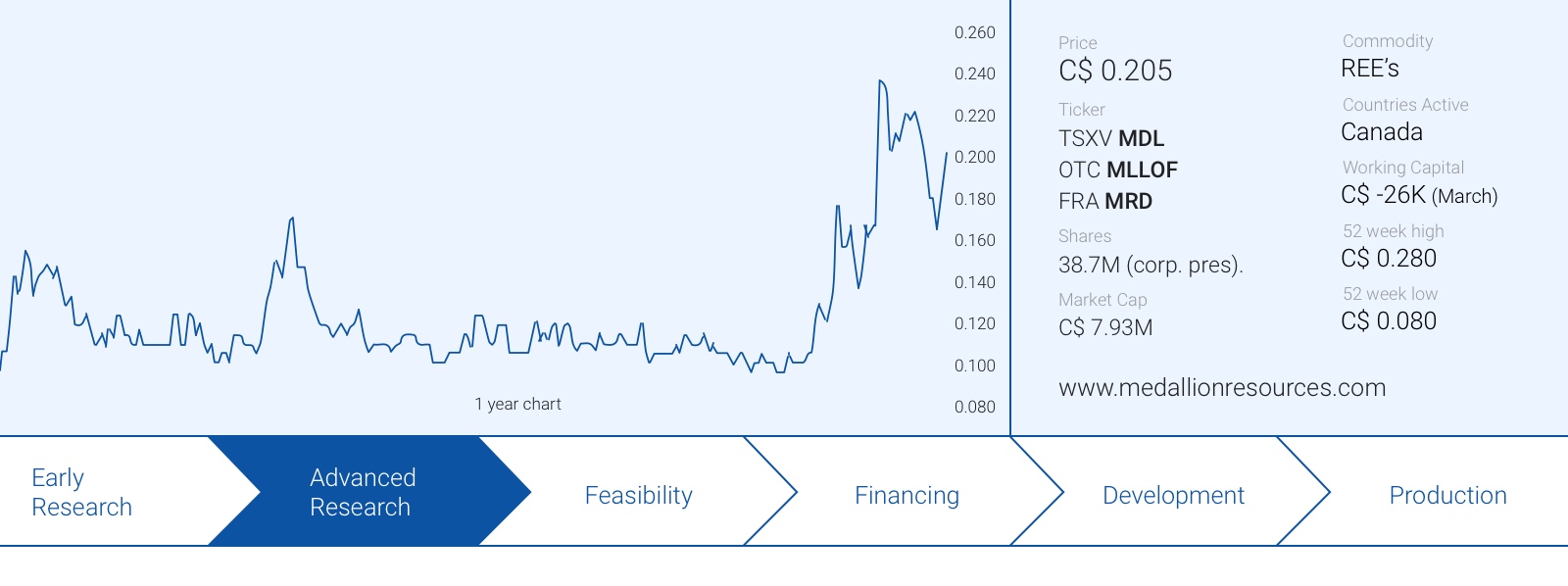

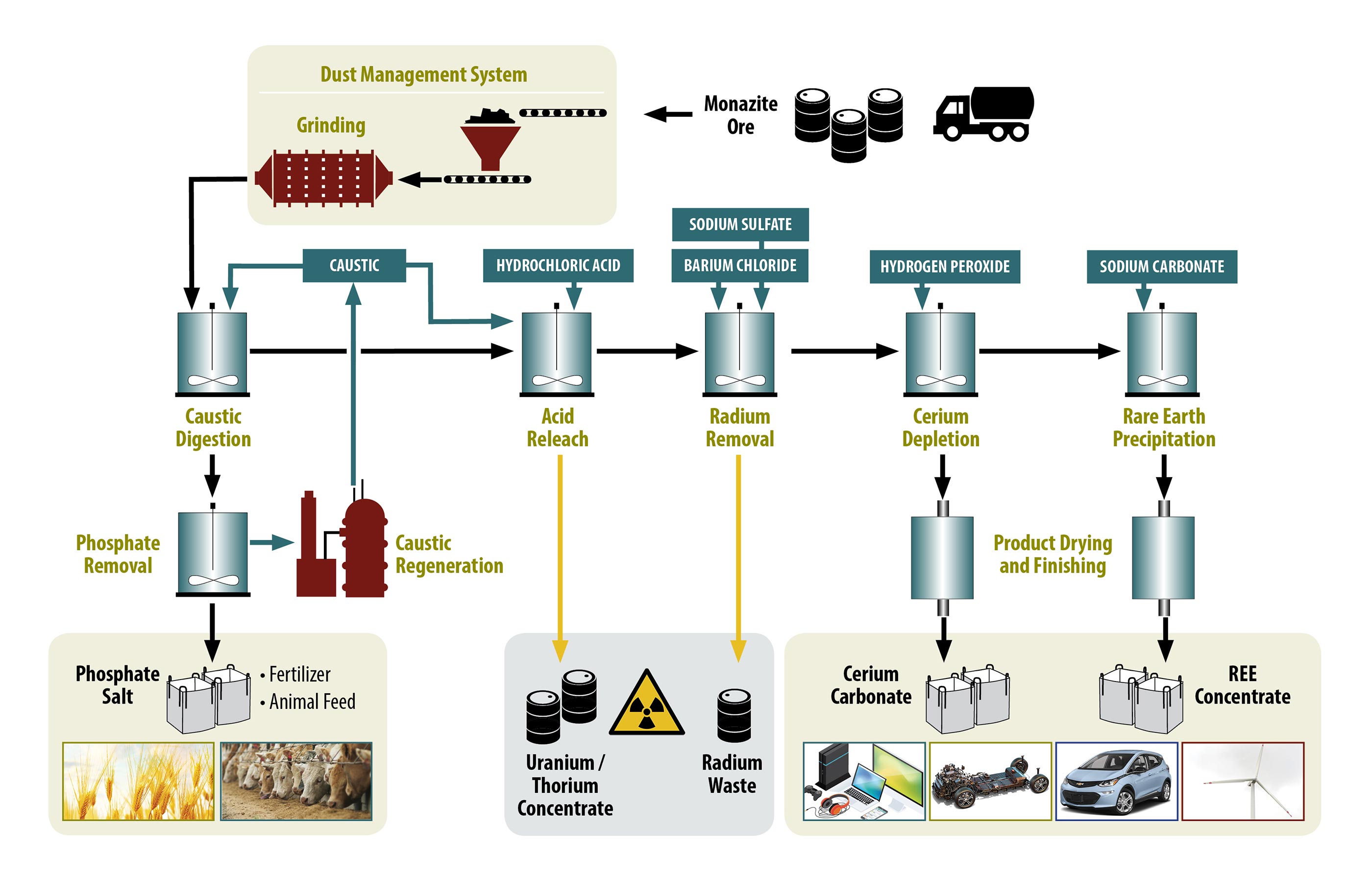

The new focus on the Rare Earth space also created renewed interest in Medallion Resources (MDL.V), which saw its share price more than double as investors seemed to re-discover this company which is working towards recovering REEs out of monazite, a waste product of the mineral sands industry. Recovering Rare Earths from monazite isn’t exactly rocket science (as the same processes are being applied in for instance in China and India), but Medallion doesn’t want to cut any corners and continues to work diligently to improve and optimize the process.

The market’s interest in REE – finally – got rekindled

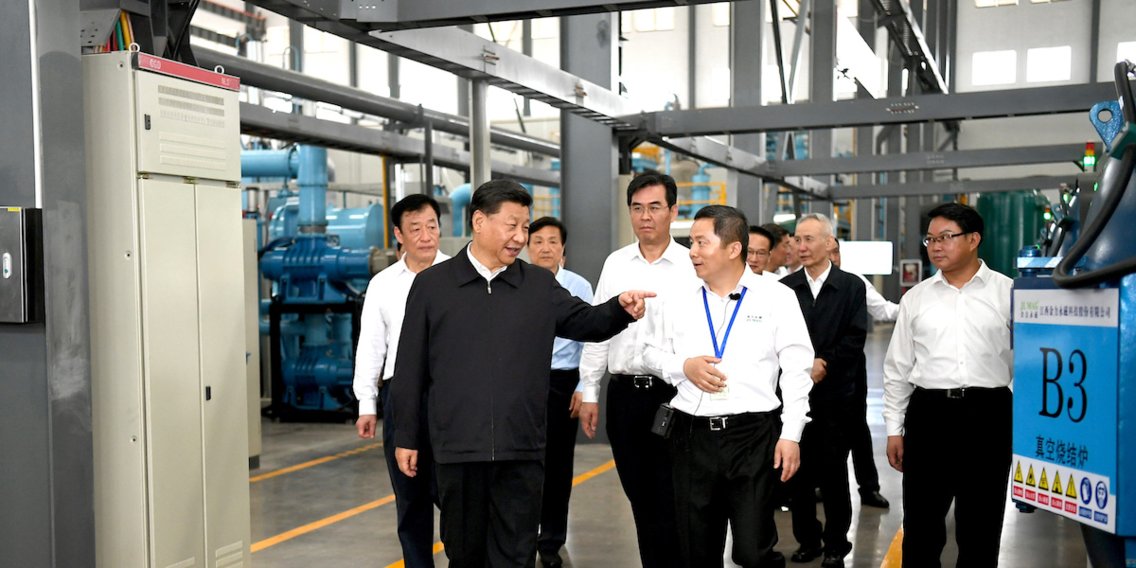

Over the past eighteen months, hardly anything exciting happened to the REE sector until a visit of the Chinese president Xi Jinping to a magnet manufacturing plant in the Jiangxi province.

This wasn’t just a ‘normal’ visit, as Xi Jinping was accompanied by the national media and his chief trade negotiator dealing with the United States to hammer out a new agreement. The visit of both the president and the negotiator was interpreted as a silent but powerful message to the Americans that although the US could continue to increase levies and import taxes on Chinese products, China does have an extremely powerful weapon that could cripple the American economy: Rare Earth Elements.

Indeed, according to the official data provided by the US Geological Survey, the United States have been importing 100% (!) of its REE needs in the past three years. More important, 80% of the REE imports are sourced from China (with the remainder coming from France and Estonia, which process and provide finished products rather than original REE concentrates). The US government has been promising to add more Rare Earth Elements to its strategic stockpile but hasn’t made much progress, indicating the US could indeed be in a China-induced stranglehold as it has no back-up plan to secure its REE needs.

Considering 72% of the 2018 REE production and 47% of the world reserves are in China and Russia, two countries the USA has been alienating, the US is making things quite difficult for itself.

Medallion continues to work on its monazite-based REE recovery process

The ongoing test work is now focusing on two important parts of the process: first of all, the company is still identifying options to reduce its expected operating costs to effectively recover the REE from the monazite, and it’s working with a team of the University of Toronto to establish the thermodynamic models of phosphate conversion and caustic regeneration projects. We are very interested in gaining additional insight in the phosphate data, as this could be an interesting by-product of the process.

Approximately one third of monazite consists of phosphate and if this could be recovered and processed into a saleable product, the revenue from phosphate sales could help to reduce the production cost of the REE’s, which are the real money makers for Medallion. As a reminder, thex federal government is subsidizing this test work for approximately 75% of its total cost.

Parallel to figuring out further cost saving measures, Medallion also continues to work on dealing with the waste materials that will be created by the process. The Saskatchewan Research Council is currently analyzing these waste streams and the results will be shared with waste processors and waste disposal firms to determine the best option to deal with it. And CEO Don Lay knows his way in the subsidy landscape as 60% of this activity will be subsidized by the government as well.

By using subsidies where possible, Medallion Resources doesn’t need huge amounts of money to further refine its flow sheet and the C$600,000 it raised at the end of the first quarter will go a long way. Medallion is currently entering into discussions with engineering groups to get some price quotes for a full-sized production plant and this will help us to further finetune our economic model.

Medallion has also recently issued a tender process to call for third party proposals for the process engineering design of the plant. Those third parties will be able to use the research that has already been completed by the Saskatchewan Research Council as starting point, and the inputs (predominantly the expected capital expenditures and operating expenditures) will go a long way to determine the economics of a monazite-to-REE processing plant.

A quick look at the current REE prices

So what was the impact of the recent nervousness on the REE prices? We are comparing the current prices with the September 2017 and January 2016 REE prices. Note; there are several pricing sources which usually are very close to each other. We used the publicly available prices on price.metals.com. Keep in mind there may be a margin of error of 1-3% on these prices.

The conclusion might surprise you, but despite the recent tensions, the current REE prices are still lower than the levels achieved in September 2017 when a spark briefly set the market on fire. So unlike what most market commentators would like you to believe, the REE prices are NOT going through the roof, but the renewed interest in the entire sector is a blessing for companies like Medallion Resources that are working on a plan to produce REEs that would even work at the current REE prices.

What’s the impact of the higher REE prices on Medallion’s basket price?

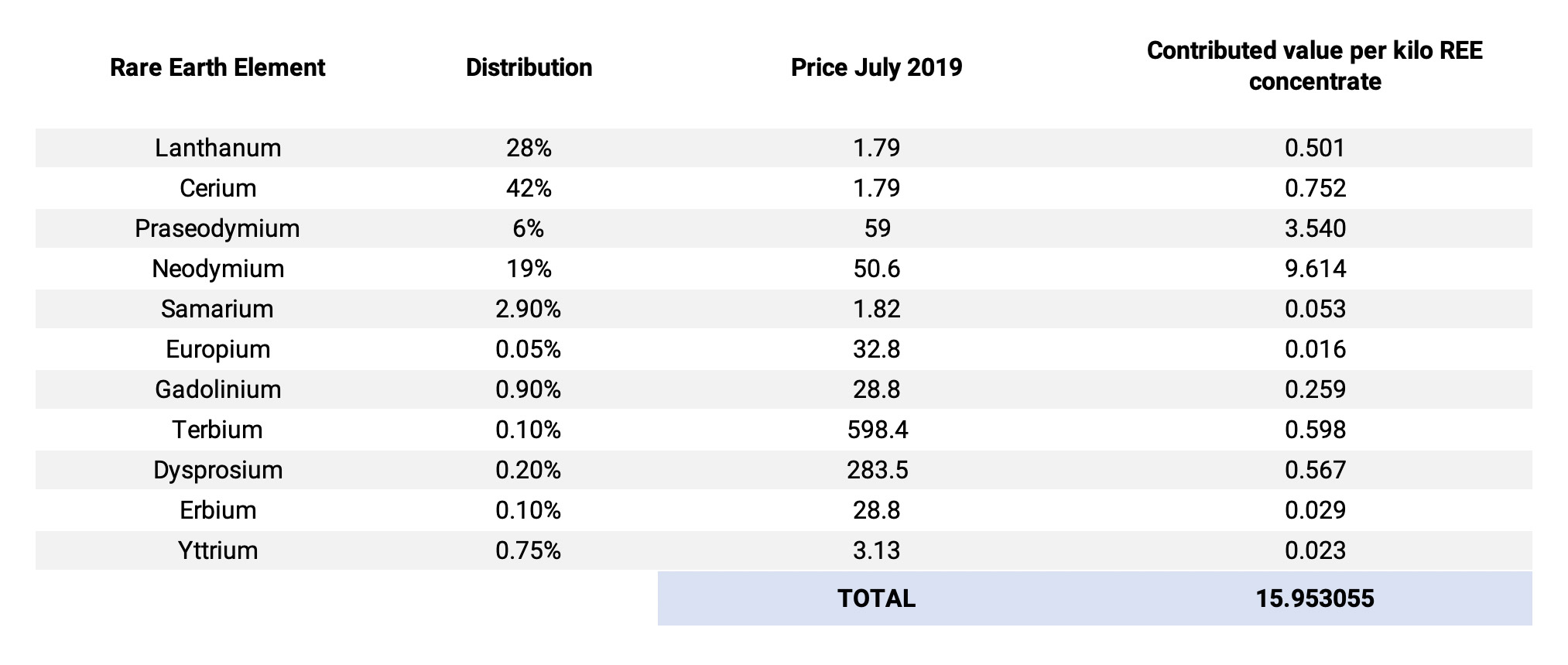

We can now apply the known REE prices to the basket of the Rare Earth Elements that can be found in the monazite. Please note the distribution percentages are illustrative. No two sources of monazite have the exact same distribution, and depending on where Medallion Resources will effectively purchase its monazite, these percentages (and thus the dollar value per kilo of REE concentrate) could change depending on the source. As such, please consider this basket price calculation to be for informational purposes only.

We have worked out two scenarios. The first scenario is the standard scenario which includes the cerium in the ‘normal’ REE concentrate.

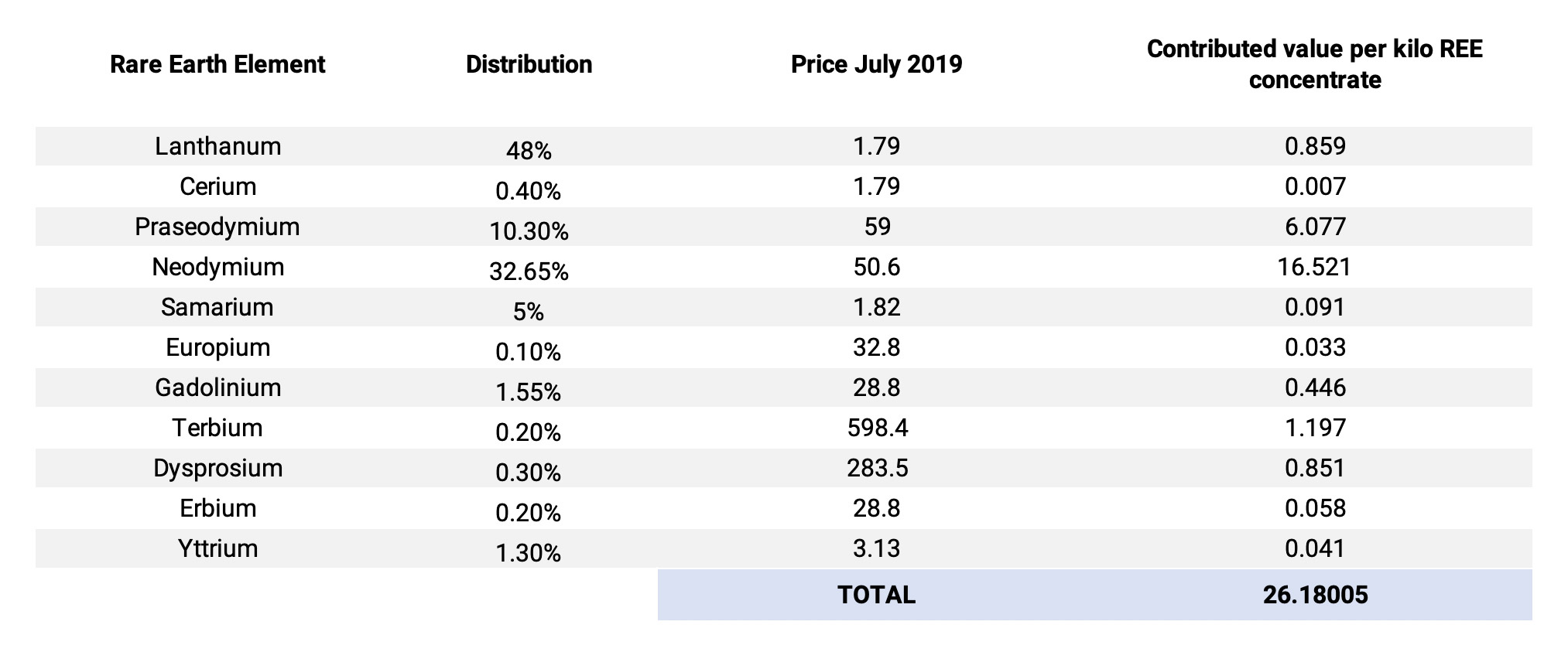

In a second scenario, we will apply the results of the cerium removal test work, which would add a lot of value to the final REE concentrate (as cerium isn’t valuable). As you may remember, Medallion Resources successfully completed additional metallurgical test work in 2018 which redufced the cerium content to a mere 0.21% in the final concentrate. And that’s a massive improvement compared to the 42% it represented in the ‘standard’ scenario. We have rounded the updated distribution percentage, so once again, this example and calculation is only meant for illustrative purposes.

As you can see in the table above, removing the cerium has a huge impact on the basket price (which increases by 64%), so if Medallion is indeed able to separate the cerium from the concentrate (at an acceptable price), it would make a lot of sense for the company to just do so. And that’s of course all part of the ongoing test work and in an ideal scenario the revenue of a specific cerium concentrate would be sufficient to cover the separation expenses.

The ongoing test work will also provide the company with a more detailed cost overview as both the operating expenses as well as the initial capex to effectively build a processing plant are still unknown at this point.

Another reason why we wouldn’t want Medallion to cut corners to speed up the process, as rush jobs usually end in tears.

Where will the plant be built?

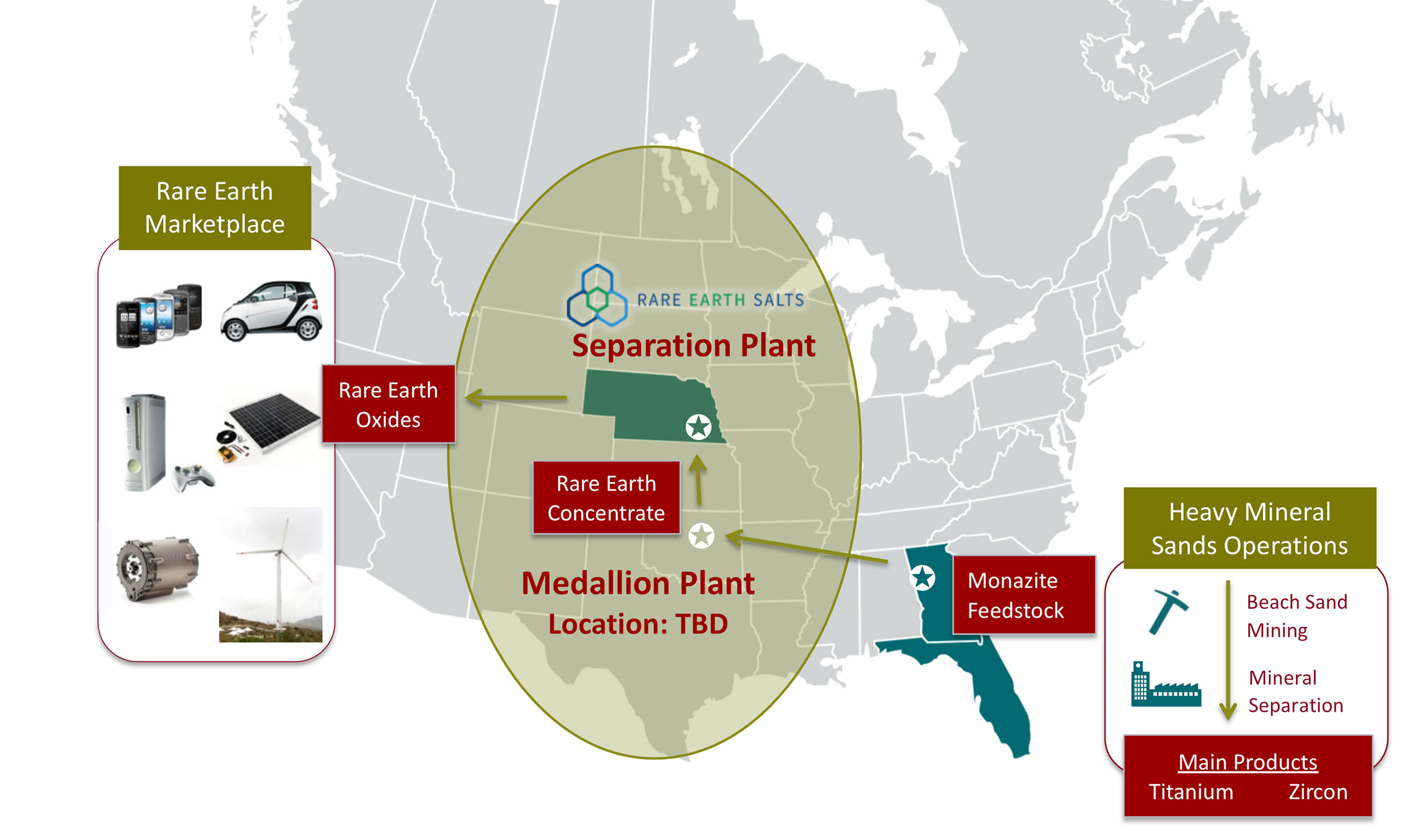

Until recently, we assumed Medallion’s preferred location for its extraction plant was Saskatchewan as the Canadian province has plenty of experience to deal with the (albeit low) values of uranium and thorium in the monazite. Additionally, as the Saskatchewan Research Council has been one of Medallion’s partners to develop the flow sheet, we thought Saskatchewan was Medallion’s best option.

But based on this week’s news update, it looks like Medallion is keeping all its options open and is now considering to build the plant in the United States as well. And that would make sense. The logistics work out better as a shorter distance and/or an easier way to transport the monazite from the port of entry (in case of an international shipment) to the plant and building the plant closer to the potential off-takers of the REE concentrate could allow Medallion to generate additional cost savings. Additionally, some US cities (and perhaps states) would welcome these higher-paying technology and processing related jobs with open arms and perhaps provide a few (local) tax breaks. With rare-earth once again in the news there is renewed interest among American investors for rare-earths plays. They would certainly be keen on such a plant close to home – with little competition.

In any case, Medallion won’t rush its decision as to where it will build the plant and the company will take the decision that makes the most sense on the economic level.

Some of the warrants are now in the money, and could provide continuous cash inflow

Fortunately, Medallion Resources spends its money wisely and the total cash operating expenses in FY 2019 (which ended in March) came in at just C$670,000. This also includes in excess of a quarter of a million spent on ‘consulting fees’ which are undoubtedly related to the advancement of the monazite processing flow sheet (as these costs are expensed and not capitalized). The effective cash outflow is even lower than the aforementioned C$670,000 as some of the expenses (including a part of CEO Don Lay’s salary) are being accrued (at a relatively low cost) instead of being paid out immediately.

Medallion Resources is a company that understands the value of a dollar, and it tries to work as cost-consciously as possible.

As of the end of March, Medallion Resources had a working capital deficit of C$26,000 despite closing a financing in that quarter. This doesn’t worry us as the majority of the short-term liabilities are the aforementioned accrued salaries and fees payable to the Medallion management and there’s a zero chance they will play hardball on that.

Subsequent to the end of the financial year, Medallion Resources received a final tranche of C$37,000 of the C$0.09 placement while in the subsequent three months (April 1st – June 25th), an additional C$62,000 in cash came in from the exercise of 418,000 warrants.

We were hoping some additional warrants would be exercised and that this would provide a continuous inflow of money, but now Medallion’s share price has come off its highs in the mid-20 cent range, it’s doubtful a lot of the C$0.15 warrants will be exercised in the near term.

Conclusion

With the renewed interest in the REE space, we expect several new companies to pop up, but don’t be fooled as projects that didn’t work 2 or 3 years ago, still won’t work at today’s REE prices.

While most mining operations (and probably all non-producing assets at this point) would still need to see a substantially higher REE price to justify the development of their respective properties, this effectively is an issue Medallion Resources won’t have to deal with. The price of its input (the monazite) will fluctuate along with the REE prices which should mitigate the impact of lower REE prices on its operating margins.

We would obviously prefer to see sustainable higher REE prices, but the main takeaway here would be that Medallion Resources isn’t your average mining company. The company should be seen as a technology company capitalizing on the potential to convert a waste product into an REE concentrate.

Disclosure: Medallion Resources is a sponsoring company, we hold a long position.